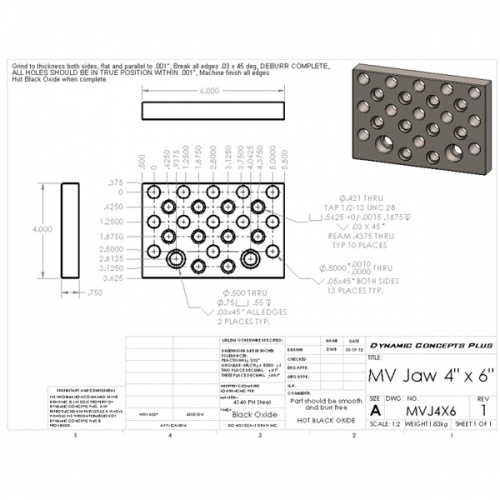

So you designed a part. You have a solid model but that isn't enough. This thing has tolerances. Serious ones. You need a good blueprint to go with the solid model that explains the need for hole size, squareness, perpendicularity, parallelism and flatness. Holes have got to be in the right place within tenths of a thousandth. Whoever makes these for you needs to know how tight things have to be. Price is for an hour of time with a CAD specialist. Buy an hour, send in your notes and several times you can be available.